Industrial operations require reliable power solutions that can withstand demanding conditions while maintaining consistent performance. A generator set serves as the backbone of power continuity for manufacturing facilities, data centers, hospitals, and construction sites worldwide. Modern industrial applications demand more than basic power generation - they require sophisticated systems that integrate seamlessly with existing infrastructure while providing optimal fuel efficiency and minimal environmental impact. The selection of an appropriate generator set involves careful consideration of load requirements, operational environment, and long-term maintenance needs.

Power reliability has become increasingly critical as industrial processes become more automated and digitally dependent. A single power interruption can result in significant financial losses, equipment damage, and safety hazards. Therefore, investing in a high-quality generator set represents not just an operational necessity but a strategic business decision that protects valuable assets and ensures continuous productivity. The evolution of generator technology has introduced advanced control systems, improved fuel efficiency standards, and enhanced emission control measures that align with modern environmental regulations.

Understanding Industrial Power Requirements

Load Assessment and Capacity Planning

Determining the appropriate generator set capacity requires comprehensive analysis of electrical loads, including both continuous and intermittent power demands. Industrial facilities typically operate multiple systems simultaneously, from heavy machinery and HVAC equipment to critical computing infrastructure and safety systems. Peak demand calculations must account for motor starting currents, which can be several times higher than running currents, ensuring the generator set can handle sudden load increases without voltage drops or frequency deviations.

Professional load analysis involves measuring actual power consumption over extended periods, identifying demand patterns, and projecting future expansion needs. This data-driven approach prevents both undersizing, which leads to overloaded generators and reduced lifespan, and oversizing, which results in inefficient fuel consumption and unnecessary capital expenditure. Modern generator set controllers provide sophisticated load management capabilities that optimize performance across varying demand scenarios.

Power Quality Standards and Compatibility

Industrial equipment requires stable voltage and frequency to operate effectively, making power quality a critical consideration in generator set selection. Sensitive electronic equipment, programmable logic controllers, and variable frequency drives are particularly susceptible to voltage fluctuations and harmonics. A properly specified generator set incorporates voltage regulation systems that maintain output within acceptable tolerances, typically ±1% for voltage and ±0.25% for frequency under steady-state conditions.

Harmonic distortion caused by non-linear loads can affect both the generator set and connected equipment, requiring careful attention to total harmonic distortion limits. Modern generator sets employ advanced alternators with robust designs that minimize harmonic generation while maintaining efficiency. Power factor considerations also play a crucial role, as poor power factor increases current draw and reduces system efficiency, requiring generators with appropriate reactive power capabilities.

Diesel Generator Technology and Advantages

Engine Performance and Reliability

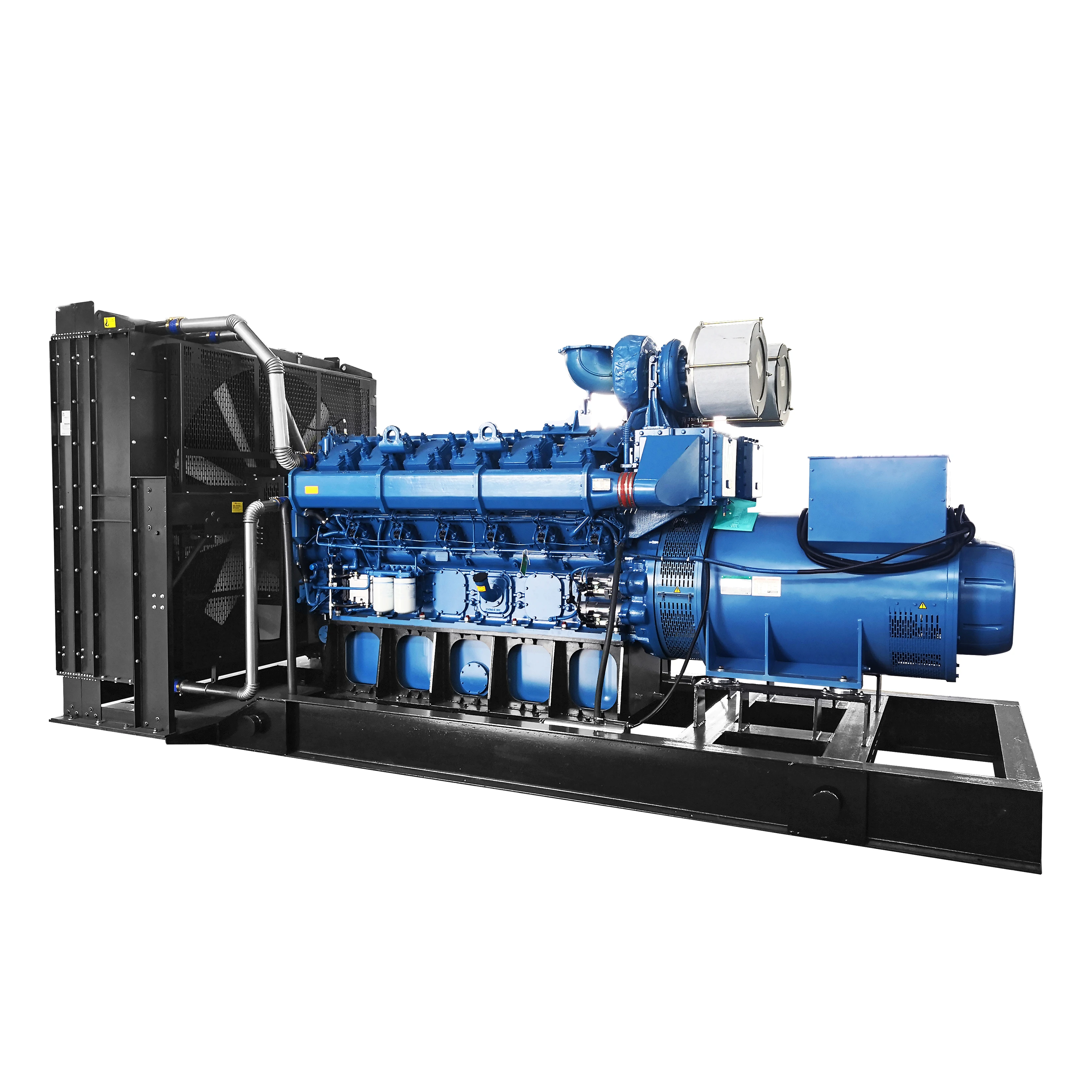

Diesel engines have established themselves as the preferred choice for industrial generator applications due to their exceptional reliability, fuel efficiency, and longevity. Modern diesel generator set designs incorporate advanced combustion technologies that maximize power output while minimizing fuel consumption and emissions. Turbocharged and intercooled engines provide superior power-to-weight ratios, enabling compact installations without compromising performance capabilities.

The robust construction of diesel engines allows them to operate continuously under full load conditions for extended periods, making them ideal for prime power applications where grid electricity is unavailable or unreliable. Electronic engine management systems monitor critical parameters such as coolant temperature, oil pressure, and fuel levels, providing early warning of potential issues and enabling predictive maintenance strategies that maximize uptime and minimize operational costs.

Fuel Efficiency and Operating Economics

Fuel efficiency directly impacts the total cost of ownership for any generator set installation, particularly in continuous-duty applications. Modern diesel engines achieve thermal efficiencies exceeding 40%, translating to lower fuel consumption per kilowatt-hour generated compared to alternative technologies. Advanced fuel injection systems with common rail technology and electronic control optimize combustion timing and fuel delivery across all operating conditions.

The economic advantages of diesel fuel include widespread availability, stable pricing compared to gaseous fuels, and excellent storage characteristics that allow for long-term fuel reserves without significant degradation. Diesel generator sets also demonstrate superior load acceptance capabilities, responding rapidly to sudden load changes without compromising stability or efficiency. This responsiveness is particularly valuable in industrial applications where equipment startup sequences can create significant transient loads.

Silent and Enclosed Generator Solutions

Acoustic Engineering and Noise Control

Industrial generator set installations often require sophisticated noise control measures to comply with local regulations and maintain acceptable working environments. Silent canopy designs incorporate multi-layer acoustic materials, strategically placed ventilation systems, and vibration isolation technologies that significantly reduce noise emissions without compromising cooling or maintenance accessibility. Sound-attenuated enclosures can achieve noise levels below 65 dB(A) at seven meters, making them suitable for installation in noise-sensitive environments.

The acoustic design process involves careful analysis of noise sources, including engine combustion, cooling fan operation, and exhaust gas flow. Advanced silencer systems with reactive and absorptive elements effectively reduce exhaust noise while maintaining optimal engine back-pressure levels. Vibration isolation mounts prevent structural transmission of engine vibrations, further reducing overall noise levels and protecting building structures from fatigue stress.

Weather Protection and Environmental Durability

Enclosed generator set designs provide comprehensive protection against environmental factors that could compromise equipment reliability and longevity. Weather-resistant enclosures feature corrosion-resistant materials, sealed electrical connections, and drainage systems that prevent moisture accumulation while maintaining adequate ventilation for optimal engine cooling. These protective measures are essential for outdoor installations exposed to temperature extremes, precipitation, and airborne contaminants.

The enclosure design must balance protection with accessibility for routine maintenance and service operations. Removable panels, integrated lifting points, and strategic component placement ensure that maintenance personnel can perform required tasks safely and efficiently. Climate control options, including heaters and ventilation fans, maintain optimal operating conditions for electronic components and prevent condensation-related issues in humid environments.

Advanced Control Systems and Monitoring

Automatic Transfer Switch Integration

Modern generator set installations incorporate sophisticated automatic transfer switches that seamlessly transition between utility and generator power without interrupting critical loads. These systems continuously monitor utility power quality parameters and initiate generator startup sequences when predetermined thresholds are exceeded. Transfer switch coordination ensures proper generator warm-up periods and synchronized switching to prevent equipment damage or operational disruptions.

Advanced transfer switch designs include bypass provisions for maintenance operations, allowing continued power supply while servicing the automatic switching equipment. Load bank testing capabilities enable periodic verification of generator set performance without disconnecting critical loads, supporting comprehensive preventive maintenance programs that ensure long-term reliability.

Remote Monitoring and Diagnostics

Contemporary generator set control systems provide comprehensive remote monitoring capabilities that enable real-time performance assessment and proactive maintenance management. Web-based interfaces allow facility managers to access generator status information, operating parameters, and maintenance schedules from any internet-connected device. Automated alarm notifications via email, SMS, or mobile applications ensure immediate awareness of any operational issues requiring attention.

Data logging functions capture detailed performance metrics over extended periods, enabling trend analysis and optimization of operating parameters. This information supports evidence-based maintenance decisions and helps identify potential issues before they result in equipment failures. Integration with building management systems and SCADA networks enables centralized control of multiple generator sets and coordination with other facility systems for optimal overall performance.

Installation Considerations and Best Practices

Site Preparation and Infrastructure Requirements

Proper site preparation forms the foundation for reliable generator set operation and longevity. Concrete pads must be designed to support the combined weight of the generator set, fuel tank, and any additional equipment while providing adequate drainage and preventing settling. Vibration isolation measures, including spring or rubber mounting systems, prevent transmission of engine vibrations to building structures and reduce noise levels.

Electrical infrastructure requirements include appropriately sized cables, protective devices, and grounding systems that comply with local electrical codes and safety standards. Fuel supply systems must incorporate leak detection, overflow prevention, and environmental protection measures that meet regulatory requirements. Adequate ventilation provisions ensure sufficient combustion air supply and heat rejection while preventing recirculation of exhaust gases.

Maintenance Access and Safety Considerations

Generator set installations must provide safe and convenient access for routine maintenance operations and emergency repairs. Service clearances around the equipment should exceed manufacturer specifications to accommodate maintenance procedures and potential equipment removal. Proper lighting, ventilation, and safety equipment storage ensure that maintenance personnel can work safely under all conditions.

Fire suppression systems appropriate for diesel fuel and electrical equipment provide additional safety protection, particularly in enclosed installations. Emergency shutdown systems with clearly marked controls enable rapid generator set shutdown in emergency situations. Spill containment measures for fuel and lubricating oil prevent environmental contamination and facilitate cleanup of any accidental releases.

Maintenance Programs and Lifecycle Management

Preventive Maintenance Strategies

Comprehensive preventive maintenance programs are essential for maximizing generator set reliability and extending equipment lifespan. Scheduled maintenance intervals based on operating hours, calendar time, and fuel consumption ensure that all critical components receive appropriate attention before wear-related failures occur. Engine oil analysis programs provide early detection of internal wear, contamination, and other conditions that could lead to premature failure.

Battery maintenance, cooling system service, and fuel system cleaning represent critical elements of any preventive maintenance program. Load bank testing at regular intervals verifies generator set performance under full-load conditions and identifies potential issues that might not be apparent during light-load operation. Documentation of all maintenance activities creates valuable historical records that support warranty claims and equipment lifecycle planning.

Parts Availability and Service Support

Access to genuine replacement parts and qualified service support significantly impacts generator set lifecycle costs and downtime risks. Establishing relationships with authorized dealers and maintaining critical spare parts inventory reduces mean time to repair during equipment failures. Service agreements that include regular maintenance, emergency repair coverage, and parts supply can provide predictable operating costs and improved reliability.

Training programs for facility maintenance personnel enhance their ability to perform routine maintenance tasks and recognize early warning signs of potential problems. This internal capability reduces dependence on external service providers for routine tasks while ensuring that major repairs and complex troubleshooting receive appropriate expert attention. Proper training also improves safety outcomes and reduces the risk of maintenance-related equipment damage.

Environmental Compliance and Sustainability

Emission Control Technologies

Modern generator set designs incorporate advanced emission control technologies that comply with increasingly stringent environmental regulations while maintaining optimal performance and reliability. Diesel particulate filters, selective catalytic reduction systems, and exhaust gas recirculation technologies work together to minimize nitrogen oxides, particulate matter, and other regulated emissions. These systems require careful integration with engine management systems to ensure proper operation across all load conditions.

Compliance with emission standards such as EPA Tier 4 Final and EU Stage V requires sophisticated aftertreatment systems that add complexity but provide significant environmental benefits. Regular maintenance of emission control components, including filter regeneration cycles and catalyst replacement, maintains system effectiveness throughout the generator set lifecycle. Proper fuel quality and appropriate operating procedures are essential for optimal emission control system performance.

Fuel Management and Efficiency Optimization

Fuel management strategies that minimize consumption and environmental impact include optimized generator sizing, load management systems, and advanced engine control technologies. Variable speed generator sets that adjust engine rpm based on load demand can achieve significant fuel savings in applications with varying power requirements. Load sharing capabilities allow multiple generator sets to operate at optimal efficiency points while providing redundancy and maintenance flexibility.

Fuel quality management programs ensure that stored diesel fuel maintains appropriate specifications for optimal combustion and emission control system operation. Water separation, filtration, and fuel conditioning systems prevent contamination-related problems that could affect engine performance or emission compliance. Biofuel compatibility enables the use of renewable fuel sources that reduce carbon footprint while maintaining reliable operation.

FAQ

What factors should be considered when sizing a generator set for industrial applications?

Generator set sizing requires comprehensive analysis of electrical loads including continuous power requirements, starting currents for motors and other equipment, future expansion plans, and power quality needs of connected equipment. Professional load assessment should account for diversity factors, environmental conditions, and altitude effects on engine performance. It's essential to consider both prime power rating for continuous operation and standby power rating for emergency use applications.

How often should industrial generator sets undergo maintenance and testing?

Maintenance intervals depend on operating hours, environmental conditions, and manufacturer recommendations, but typically include weekly visual inspections, monthly exercise periods under load, quarterly comprehensive inspections, and annual major service including oil changes, filter replacements, and cooling system service. Load bank testing should be performed annually or after extended periods of light-load operation to verify full-power capability and identify potential issues before they cause failures.

What are the advantages of diesel generator sets compared to natural gas alternatives?

Diesel generator sets offer superior fuel efficiency, longer engine life, better load acceptance characteristics, and fuel storage advantages compared to natural gas units. Diesel fuel has higher energy density, can be stored on-site for extended periods without degradation, and is not dependent on utility gas supply infrastructure. Diesel engines also demonstrate better performance at altitude and in extreme temperature conditions while requiring less frequent maintenance intervals.

How can noise levels be minimized for industrial generator set installations?

Noise reduction strategies include sound-attenuated enclosures with multi-layer acoustic materials, vibration isolation mounting systems, properly designed exhaust silencers, and strategic placement away from noise-sensitive areas. Advanced acoustic engineering can achieve noise levels below 65 dB(A) at seven meters distance. Additional measures include acoustic barriers, proper ventilation design that doesn't compromise noise control, and consideration of prevailing wind directions for optimal acoustic performance.

Table of Contents

- Understanding Industrial Power Requirements

- Diesel Generator Technology and Advantages

- Silent and Enclosed Generator Solutions

- Advanced Control Systems and Monitoring

- Installation Considerations and Best Practices

- Maintenance Programs and Lifecycle Management

- Environmental Compliance and Sustainability

-

FAQ

- What factors should be considered when sizing a generator set for industrial applications?

- How often should industrial generator sets undergo maintenance and testing?

- What are the advantages of diesel generator sets compared to natural gas alternatives?

- How can noise levels be minimized for industrial generator set installations?