The Evolution of Modern Power Generation Solutions

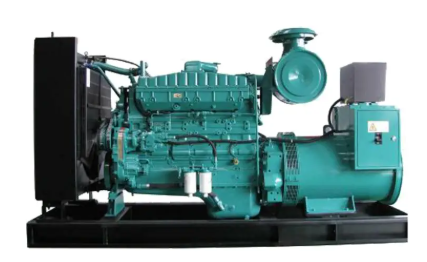

The landscape of power generation has transformed dramatically over the past decade, with customizable diesel generators emerging as the cornerstone of reliable energy solutions. These versatile power systems have revolutionized how businesses and industries approach their energy needs, offering unprecedented flexibility and efficiency in power generation.

In today's dynamic business environment, one-size-fits-all solutions no longer meet the diverse requirements of modern operations. The advent of customizable diesel generators has introduced a new era of power solutions that can be precisely tailored to specific applications, ensuring optimal performance while maximizing cost-effectiveness.

Understanding Customization Options for Diesel Generators

Power Output and Sizing Specifications

When considering customizable diesel generators, power output capabilities stand as a primary consideration. Modern generators can be configured to deliver anywhere from a few kilowatts to several megawatts, depending on the application requirements. This flexibility ensures that businesses only invest in the capacity they truly need, avoiding unnecessary overhead costs.

The sizing specifications extend beyond mere power output. Physical dimensions, weight restrictions, and installation requirements can all be customized to suit specific site conditions. This level of customization proves particularly valuable in situations where space is at a premium or where generators need to be integrated into existing infrastructure.

Fuel System Modifications

The fuel system represents another crucial area where customizable diesel generators offer significant advantages. Advanced fuel tank configurations can be designed to meet extended runtime requirements, while sophisticated fuel filtration systems ensure optimal performance even in challenging environments.

Modern fuel systems can also be adapted to accommodate various fuel types and qualities, making customizable diesel generators suitable for deployment in remote locations where fuel quality might vary. This adaptability ensures consistent performance and reliability regardless of operating conditions.

Advanced Control and Monitoring Systems

Digital Interface Options

The integration of sophisticated control systems has transformed how customizable diesel generators are operated and maintained. Digital interfaces can be tailored to provide real-time monitoring of critical parameters, allowing operators to optimize performance and predict maintenance needs accurately.

Modern control systems offer customizable alert thresholds, remote monitoring capabilities, and detailed performance analytics. These features enable proactive maintenance scheduling and help prevent unexpected downtime, ultimately reducing operational costs and extending equipment lifespan.

Remote Management Capabilities

The ability to remotely monitor and control customizable diesel generators has become increasingly important in today's connected world. Advanced telematics systems can be integrated to provide comprehensive oversight of generator operations from anywhere in the world.

These remote management systems can be customized to provide specific data points and control options based on user requirements. From fuel consumption monitoring to load management and maintenance scheduling, these systems offer unprecedented control over generator operations.

Environmental Considerations and Compliance

Emission Control Systems

Environmental regulations continue to evolve, making emission control a critical aspect of customizable diesel generators. Modern units can be equipped with advanced emission control systems that meet or exceed local and international standards.

From selective catalytic reduction (SCR) systems to particulate filters, these environmental solutions can be tailored to specific regulatory requirements while maintaining optimal performance. This customization ensures compliance without compromising on operational efficiency.

Noise Reduction Solutions

Sound attenuation represents another important customization aspect, particularly for installations in noise-sensitive areas. Customizable diesel generators can be equipped with various noise reduction solutions, from enhanced enclosure designs to advanced muffler systems.

These acoustic modifications can be tailored to meet specific decibel requirements while ensuring adequate ventilation and accessibility for maintenance. The result is a power solution that operates quietly without compromising on performance or reliability.

Installation and Integration Considerations

Site-Specific Customization

The successful deployment of customizable diesel generators often depends on site-specific modifications. From weatherproof enclosures for outdoor installations to specialized mounting solutions for rooftop placements, every aspect can be tailored to match the installation environment.

Integration with existing power infrastructure requires careful consideration of electrical specifications, switchgear requirements, and load management systems. These elements can be customized to ensure seamless operation within the broader power distribution network.

Maintenance Access Design

Serviceability represents a crucial aspect of generator customization. Access points, maintenance bays, and service corridors can be designed to facilitate routine maintenance and repairs, even in challenging installation locations.

These customizations extend to the placement of key components, ensuring that maintenance personnel can easily access critical parts without compromising safety or operational efficiency.

Frequently Asked Questions

What factors should I consider when customizing a diesel generator?

Consider your power requirements, site conditions, environmental regulations, noise restrictions, and maintenance accessibility. Also evaluate fuel availability, runtime requirements, and integration needs with existing infrastructure.

How long does it take to design and build a customized diesel generator?

The timeline varies depending on the complexity of customization requirements. Typically, the process takes 8-16 weeks from initial design to final installation, including engineering, manufacturing, and testing phases.

Can existing diesel generators be customized or modified?

Many existing generators can be modified to some extent, particularly in terms of control systems, monitoring capabilities, and environmental features. However, major structural or power output modifications may require a new unit.

What maintenance considerations are unique to customized generators?

Customized generators may require specialized maintenance procedures and specific spare parts. It's important to establish a maintenance plan that accounts for custom components and ensures proper training for maintenance personnel.