Understanding the Evolution of Modern Power Generation Solutions

The landscape of portable power generation has transformed dramatically over the years, with diesel generators emerging as a cornerstone of reliable power supply across various industries and applications. As businesses and individuals seek dependable power solutions, the choice between silent and open-frame diesel generators has become increasingly significant. These two distinct configurations each offer unique advantages that cater to different operational requirements and environmental considerations.

The market for diesel generators continues to expand, driven by increasing demand for backup power solutions and the need for reliable power in remote locations. Whether you're powering a construction site, providing emergency backup for a healthcare facility, or supporting off-grid operations, understanding the key differences between silent and open-frame options is crucial for making an informed decision.

Design Features and Construction Differences

Silent Generator Enclosure Technology

Silent diesel generators represent the pinnacle of modern engineering in noise reduction and environmental consideration. These units feature sophisticated acoustic enclosures constructed with multiple layers of sound-dampening materials. The enclosure typically incorporates high-density foam insulation, vibration-isolating mounts, and carefully designed air flow paths that minimize noise while maintaining optimal operating temperatures.

The construction includes strategic placement of cooling systems and exhaust components, ensuring that sound waves are effectively trapped and dissipated within the enclosure. This advanced design typically results in noise levels as low as 60-70 decibels at a distance of 7 meters, comparable to normal conversation levels.

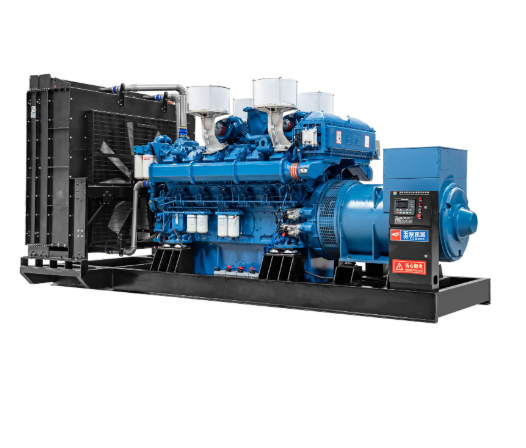

Open-Frame Configuration Characteristics

Open-frame diesel generators feature a more traditional and straightforward design approach. These units expose the core components, including the engine, alternator, and control panel, within a robust steel frame. The open configuration facilitates easier access for maintenance and repairs, while also promoting natural air circulation for cooling.

The structural simplicity of open-frame models often translates to lower initial costs and reduced weight. However, this design typically results in higher noise levels, usually ranging from 80-95 decibels, which can be a significant consideration depending on the application environment.

Performance and Operational Considerations

Power Output and Efficiency Analysis

When it comes to power generation capacity, both silent and open-frame diesel generators can deliver comparable output levels. The key difference lies in how they manage heat dissipation and fuel efficiency. Silent generators often incorporate advanced cooling systems to compensate for the enclosed design, while open-frame units rely on natural airflow.

Fuel efficiency can vary between the two types, with modern silent generators often featuring sophisticated fuel management systems that can optimize consumption. However, the additional weight of the acoustic enclosure may impact the overall efficiency in mobile applications.

Maintenance and Accessibility Features

Maintenance requirements differ significantly between the two designs. Open-frame diesel generators offer immediate access to all components, making routine maintenance and repairs more straightforward. Technicians can easily inspect, service, or replace parts without navigating through enclosure panels.

Silent generators, while requiring additional steps to access internal components, often incorporate thoughtful design features such as large access doors and removable panels. Many modern silent units also include advanced monitoring systems that can alert operators to maintenance needs before issues become critical.

Environmental Impact and Compliance

Noise Pollution Management

The most apparent environmental advantage of silent diesel generators is their superior noise management capabilities. This makes them ideal for urban environments, residential areas, and noise-sensitive locations such as hospitals or educational institutions. The reduced noise pollution also helps organizations comply with local noise ordinances and environmental regulations.

Advanced sound attenuation features in silent generators can reduce noise levels by up to 25-30 decibels compared to their open-frame counterparts. This significant reduction can make the difference between requiring special permits or being able to operate freely in noise-restricted zones.

Emissions Control and Environmental Standards

Both types of diesel generators must meet increasingly stringent emissions standards. Silent generators often incorporate additional features such as improved exhaust systems and catalytic converters, which can help reduce harmful emissions. The enclosed design also provides better control over exhaust direction and dispersal.

Open-frame generators, while meeting basic emissions requirements, may require additional modifications or accessories to achieve the same level of environmental protection. However, their simpler design can make it easier to upgrade or modify emissions control systems as regulations evolve.

Application-Specific Selection Criteria

Industrial and Construction Settings

Open-frame diesel generators often excel in industrial and construction environments where noise concerns are secondary to durability and ease of maintenance. The robust design and straightforward access to components make them well-suited for harsh conditions and frequent maintenance requirements.

These settings typically have less stringent noise restrictions and prioritize reliability and power output over sound attenuation. The lower initial cost of open-frame units can also be advantageous for projects with tight budget constraints.

Commercial and Residential Applications

Silent diesel generators are typically the preferred choice for commercial and residential applications where noise control is essential. Their sophisticated design and reduced sound output make them suitable for use in urban areas, medical facilities, and other noise-sensitive environments.

These units also offer better protection against weather elements and unauthorized access, making them more secure for permanent installations. The professional appearance of enclosed units can also be an important consideration for locations where aesthetic appeal matters.

Frequently Asked Questions

What is the typical lifespan difference between silent and open-frame diesel generators?

The lifespan of both types generally ranges from 15-20 years with proper maintenance. Silent generators may have slightly longer lifespans due to better protection from environmental factors, though this can vary based on usage patterns and maintenance quality.

How significant is the cost difference between silent and open-frame models?

Silent diesel generators typically cost 20-30% more than comparable open-frame models due to their additional engineering features and materials. However, this initial cost difference should be weighed against potential long-term benefits such as better resale value and broader application possibilities.

Can an open-frame generator be converted to a silent version?

While aftermarket acoustic enclosures are available, converting an open-frame generator to match the performance of a purpose-built silent unit is challenging and often not cost-effective. The original design considerations for cooling and airflow may not be compatible with enclosed operation.

Which type requires more frequent maintenance?

Open-frame generators typically require similar maintenance intervals but may need more frequent cleaning due to exposure to environmental elements. Silent generators, while offering better protection, may need specialized attention to their cooling systems and sound-dampening components.