Essential Steps for Installing Industrial Power Generation Systems

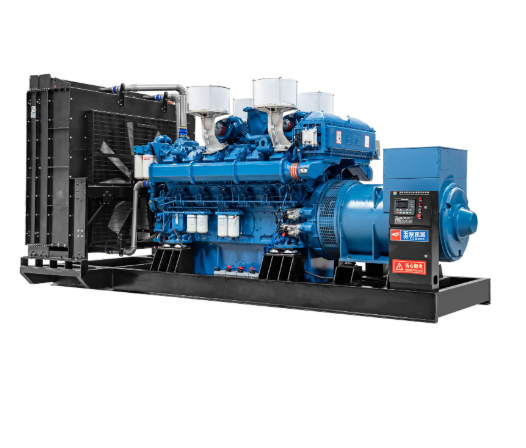

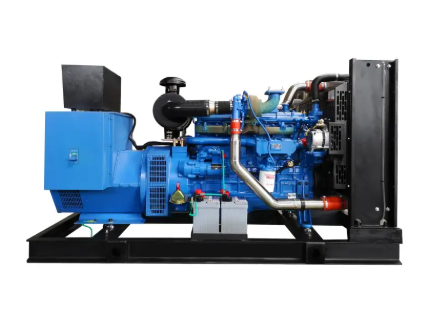

Industrial generator set installation represents a significant investment for any facility, requiring careful planning, expert knowledge, and precise execution. A properly installed generator system ensures reliable backup power, minimizes downtime, and protects valuable assets during power outages. Understanding the comprehensive process and key considerations is crucial for facility managers, contractors, and stakeholders involved in the installation project.

Pre-Installation Planning and Site Assessment

Location Selection and Space Requirements

Selecting the optimal location for your industrial generator set installation begins with a thorough site evaluation. The chosen area must provide adequate space for the generator unit itself, plus additional clearance for maintenance access, ventilation, and fuel storage systems. Consider factors such as distance from buildings, noise regulations, and local zoning requirements. The foundation must be capable of supporting the generator's weight and withstanding operational vibrations.

Environmental factors play a crucial role in location selection. Protection from flooding, extreme weather conditions, and potential hazards must be considered. Additionally, the site should allow for proper exhaust routing and minimize the impact of noise on nearby operations or residential areas.

Compliance and Permitting Process

Before proceeding with the industrial generator set installation, obtain all necessary permits and ensure compliance with local, state, and federal regulations. This includes environmental permits, building codes, fire safety requirements, and electrical codes. Working with experienced contractors who understand these requirements can streamline the permitting process and prevent costly delays.

Documentation requirements typically include detailed site plans, electrical diagrams, emissions calculations, and noise studies. Early engagement with regulatory authorities and careful attention to compliance details will facilitate a smoother approval process.

Technical Infrastructure Requirements

Fuel System Design and Implementation

The fuel system design must align with the generator's specifications and operational requirements. Whether utilizing diesel, natural gas, or other fuel types, proper storage and delivery systems are essential. Consider fuel tank capacity, piping systems, pressure regulators, and monitoring equipment. Regular maintenance access points and safety systems must be incorporated into the design.

Fuel quality management systems and filtration requirements should be addressed during the planning phase. Implementation of appropriate safety measures, including leak detection and containment systems, ensures environmental protection and regulatory compliance.

Electrical Integration and Controls

Professional electrical system integration is crucial for successful industrial generator set installation. This includes proper sizing of conductors, installation of transfer switches, and configuration of control systems. The electrical design must accommodate both normal and emergency power requirements while ensuring seamless transitions during power outages.

Modern generator installations often incorporate advanced monitoring and control systems. These systems provide real-time performance data, automated testing capabilities, and remote monitoring options. Integration with existing building management systems may require additional planning and coordination.

Installation Process and Best Practices

Equipment Handling and Positioning

Safe and precise handling of generator equipment requires specialized lifting equipment and experienced personnel. A detailed lift plan should address access routes, equipment specifications, and safety procedures. Proper positioning ensures optimal performance and maintenance accessibility while minimizing the impact on surrounding operations.

Installation teams must follow manufacturer guidelines for mounting, alignment, and connection of all components. Attention to detail during this phase prevents future operational issues and ensures warranty compliance.

System Testing and Commissioning

Comprehensive testing protocols verify proper installation and system functionality. Initial testing includes mechanical checks, electrical verification, and control system validation. Load bank testing confirms the generator's capacity to handle expected power demands under various conditions.

The commissioning process involves systematic verification of all systems and components. This includes fuel system operation, cooling systems, exhaust systems, and safety controls. Documentation of test results and system parameters provides a baseline for future maintenance and troubleshooting.

Maintenance Planning and Operation Training

Preventive Maintenance Schedules

Establishing a comprehensive maintenance program ensures long-term reliability of the generator system. Regular maintenance schedules should address all critical components, including engine systems, electrical systems, and auxiliary equipment. Documentation of maintenance procedures and requirements helps facility personnel maintain proper care of the installation.

Implementing a preventive maintenance strategy reduces the risk of unexpected failures and extends equipment life. Include provisions for emergency service response and spare parts inventory management in the maintenance plan.

Operator Training Requirements

Proper training of facility personnel is essential for successful operation and maintenance of the generator system. Training programs should cover normal operations, emergency procedures, and basic troubleshooting. Understanding system indicators and proper response protocols enables operators to maintain safe and efficient operation.

Regular refresher training and documentation updates ensure continued operational excellence. Consider incorporating hands-on training sessions and simulation exercises to build operator confidence and competence.

Frequently Asked Questions

What factors affect the total cost of industrial generator set installation?

The total cost is influenced by multiple factors including generator size and type, site preparation requirements, fuel system complexity, electrical integration needs, and local permitting requirements. Additional considerations include transportation costs, installation labor, and commissioning expenses.

How long does a typical industrial generator set installation take?

Installation timeline varies based on project scope and complexity, typically ranging from several weeks to several months. Factors affecting duration include permit acquisition, site preparation, equipment delivery, installation work, and commissioning processes.

What are the key maintenance requirements after installation?

Regular maintenance includes engine service, fuel system inspection, battery maintenance, and testing of control systems. Specific requirements depend on generator type, usage patterns, and environmental conditions. Following manufacturer-recommended maintenance schedules is essential for optimal performance and reliability.